|

| August 06, 2019 | Volume 15 Issue 29 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

2019 Powder Metallurgy Design Excellence Award winners announced

The winners of the 2019 Powder Metallurgy (PM) Design Excellence Awards Competition were announced during POWDERMET2019, the International Conference on Powder Metallurgy & Particulate Materials, at an awards luncheon June 24, 2019.

According to the Metal Powder Industries Federation (MPIF), the competition's sponsor, "powder metallurgy is a metal-forming process performed by heating compacted metal powders to just below their melting points. Although the process has existed for more than 100 years, over the past quarter century it has become widely recognized as a superior way of producing high-quality parts for a variety of important applications."

MPIF is a not-for-profit association formed by the powder metallurgy industry to advance the interests of the metal powder producing and consuming industries.

The Federation is composed of six trade associations focused on powder metallurgy, metal powders, or particulate materials.

Seven Awards of Distinction and nine Grand Prizes were given in this year's competition. Components made with metal injection molding (MIM) were also included.

Submission guidelines included:

- Any PM component was eligible provided it was in commercial production and used in end products during 2016, 2017, or 2018 for at least six months.

- All fabricators that are members of the Metal Powder Industries Federation could submit entries.

Not all submitted parts received were awarded.

The selection was based on:

- Design Configuration

- Use of innovative tooling or fabricating technique

- Shape complexity

- Close to net shape

- Engineering Properties

- Precision

- Process control

- Physical and mechanical properties and density

- End-user qualification testing

- Composition/combination of properties

- High-performance properties

- Promotional Value

- New or unusual application

- Significant cost savings

- Used in a high-visibility product

- Sustainability

----------------------------------------

AWARDS OF DISTINCTION

----------------------------------------

Automotive - Engine Category for Conventional PM components

Automotive - Engine Category for Conventional PM components

Catalus Corporation: Access-hole cover used to transfer collected oil from the crankcase ventilation system at the top of the engine into the engine block. It had to use an existing bolt pattern and have a low profile to permit clearance to the nearby engine control module. The PM part replaced an assembly of multiple stamped, machined, and drawn components and resulted in a 27 percent weight savings.

--------------------------

Automotive - Engine Category for Conventional PM components

Automotive - Engine Category for Conventional PM components

Nichols Portland LLC: Rotor vane used in an engine lubrication oil-pump system. The part is sized, face ground, deburred, and cleaned. The product application requires high accuracy of rotor radial dimensions, ID spline, and vane-slot features to reduce internal pump leakage and achieve the required system mechanical efficiency.

--------------------------

Automotive - Engine Category for MIM components

Automotive - Engine Category for MIM components

Indo-MIM Pvt. Ltd., India: Valve poppet used in the fuel-injection system of a diesel engine for heavy trucks. The extremely small part has a tight tolerance on its outside diameter and the perpendicularity of the three legs. Part-specific forms were used during sintering to maintain part quality.

--------------------------

Automotive - Transmission Category for Conventional PM components

Automotive - Transmission Category for Conventional PM components

GKN Powder Metallurgy and Ford Motor Company: Transmission park-range-sensor control bracket that acts as a stop to prevent over travel of a transmission rod in the parking system. While mechanical properties are not a major concern, the positional tolerance of the part once bolted in place is critical.

--------------------------

Automotive - Chassis Category for Conventional PM components

Automotive - Chassis Category for Conventional PM components

FMS Corporation: Fan clutch assembly components made for their customer Kit Masters and used in cooling systems for semi-tractors and other large, diesel-engine vehicles. The six PM parts included a bushing-tensioner retainer and an index coupler. All six parts are made from FC0208-50. The PM parts replaced machined components and offered a 60 percent cost savings.

--------------------------

Hand Tools/Recreation Category for Conventional PM components

Hand Tools/Recreation Category for Conventional PM components

FMS Corporation: Camshaft and water-pump sprockets made for their customer Polaris Industries. The parts are used in the Polaris Slingshot, 3-wheel, side-by-side "moto roadster." The water-pump sprocket was especially challenging, as the customer desired a one-piece shaft/sprocket design. The PM components represent a 40 percent cost savings compared with machining.

--------------------------

Hardware/Appliances Category for Conventional PM components

Hardware/Appliances Category for Conventional PM components

Webster-Hoff Corporation and their customer Humanscale: Ratcheting lock; part of the locking mechanism in an adjustable office chair arm. Unique fixturing is needed during sintering so that the part can meet the tolerances required for the post-sintering, drilling, and tapping operation.

----------------------------------------

GRAND PRIZE AWARDS

----------------------------------------

Automotive - Engine Category for Conventional PM components

Automotive - Engine Category for Conventional PM components

Capstan: Compact brushless DC actuator gear designed to optimize engine performance and reduce nitrogen oxide emissions for on- and off-road commercial diesel-engine vehicles. Made from SS-316L, all gear dimensions meet AGMA level 7 requirements. This stainless steel precision gear required unique carbide tooling for compaction.

--------------------------

Automotive - Engine Category for MIM components

Automotive - Engine Category for MIM components

Indo-MIM Pvt. Ltd., India: Turbocharger vane. The part complexity includes a thin-walled, curved profile with a thick lug on top. A two-drop, hot runner tool is used to produce 12 parts per shot without any slide involvement.

--------------------------

Automotive - Transmission Category for Conventional PM components

Automotive - Transmission Category for Conventional PM components

Stackpole International, Canada: Clutch backing plate and pressure-apply piston used in the General Motors 9T50/65 Hydra-Matic transmission. The parts form a combined sub-assembly within the transmission together with a central hub and two roller-bearing races. Compaction of the parts involves the use of multiple-element tooling, and a complex die design is needed to form the near-net-shape geometry.

--------------------------

Automotive - Chassis Category for MIM components

Automotive - Chassis Category for MIM components

Indo-MIM Pvt. Ltd., India: MIM-17-4 PH latching plate used in a collapsible roof assembly for passenger cars. A solid-film lubricant coating is applied to the part to reduce friction during operation of the collapsible roof. Molding was a challenge, as the part has two thin features joined by a thicker slotted section.

--------------------------

Lawn & Garden/Off Highway Category for Conventional PM components

Lawn & Garden/Off Highway Category for Conventional PM components

ASCO Sintering Co.: Miniature planetary gear carrier set used in a commercial rotary irrigation system. The parts are made from SS-316N1,N2 compacted to a green density of 6.6 g/cm3.

--------------------------

Hand Tools/Recreation Category for MIM components

Hand Tools/Recreation Category for MIM components

Indo-MIM Pvt. Ltd., India: Right- and left-hand bindings in ski shoes. The parts are made from MIM-4605 that is zinc-blue passivated for corrosion resistance. Previously, the parts were cast and required many secondary operations to meet the desired configuration and dimensional tolerances.

--------------------------

Industrial Motors/Controls & Hydraulics Category for Conventional PM components

Industrial Motors/Controls & Hydraulics Category for Conventional PM components

ASCO Sintering Co.: Spring seat of a hydraulic valve actuator mechanism. The part is made from SS-316H-20 and is compacted to a green density of 6.5 g/cm3 prior to sintering. The five blades of the component are long and too thin to be compacted to net shape directly, so extra material is added in the region of the blades. A low-cost turning operation is needed to achieve the final part geometry.

--------------------------

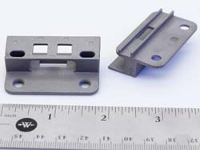

Hardware/Appliances Category for MIM components

Hardware/Appliances Category for MIM components

Indo-MIM Pvt. Ltd., India: Two MIM-17-4 PH parts, a keeper and a ramp used in a door-hinge assembly. The keeper has a thick but slotted, curved profile that extends 79 mm (~3 in.). By using three slides, two to form the hole running along the length and another to form the slot at the center, two parts are produced per shot. Previously, the parts were cast and required considerable machining to achieve the desired dimensions.

--------------------------

Medical/Dental Category for MIM components

Medical/Dental Category for MIM components

Indo-MIM Pvt. Ltd., India: MIM-17-4 PH K-mount main part used in a digital surgical camera. The challenge in molding was to develop a slide mechanism robust enough to form the y-section with ease and with precise matching to avoid flash. Previously, the part was made as two separate pieces that were subsequently welded. This tended to create sharp edges that damaged the cable during use.

Source: MPIF

Published August 2019

Rate this article

View our terms of use and privacy policy